Generator Maintenance Procedure

(800)779-3848

In this page you will find information regarding our generator maintenance procedure.

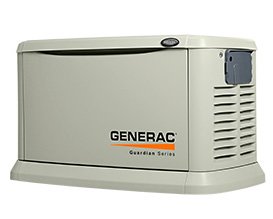

RCS Electrical Services is your standby generator repair solution provider. We are specialists, installing and servicing all the best brands of generators. We are certified by Cummins, Generac, Centurion, Kohler, Briggs and Stratton, GE and others. Contact us now if you are in need of service, installation, or repair.

Read below to view and learn more about our maintenance and service procedures.

Click here to make a generator service request

Generator Maintenance Procedure Recommended by Manufacturers

If you your standby generator is not running properly, or not running at all, you need to act right away. These units should not stay idle too long. Insects, rodents, and other animals will soon go inside your generator and cause additional damage as they make a home of it. This will undoubtedly cost hundreds of additional dollar to repair.

We are experts in terms of generator service, generator repair, generator troubleshooting, and generator diagnosis. We follow manufacturer's standard procedures to tune and calibrate your generator to their specifications.

We will make sure that when we are done, your unit is running according to manufacturer's recommendations.

Even if your machine appears to be running fine, if you have not done proper scheduled maintenance, it may be needing a tune-up and other adjustments right now.

Click here to learn more about our generator repair rates and fees.

Or click here to view our generator maintenance procedure list.

Generator Enclosure Repair or Replacement. Make Your Generator Like New Again

Before |

After |

In coastal areas, where generators are exposed to humid salty air, their enclosures tend to wear out fast due to corrosion. Often the generator and engine are in good condition, but rust has destroyed most of the enclosure, chassis, and base.

In these kinds of circumstances we recommend that you replace the enclosure rather than discard the entire generator. This is normally a costly repair, but it certainly cost less than replacing the entire generator set.

If the corrosion has not done extensive damage to the enclosure and chassis, we may recommend to have them repainted. We have a painting program in which your generator is treated in such a way that it can be restored to a very acceptable condition and afford you many years of service.

Contact us if need a generator enclosure kit replaced.

Generator Maintenance Procedure List

- Check general condition of generator

- Check all hoses and belts. Tighten and adjust if necessary

- Check all fluid levels and top off

- Check all field electrical connections for tightness and contact.

- Clean generator when necessary

- Start generator and warm up

- Transfer power from utility to generator

- Check load and voltage output, calibrate if necessary

- Check output frequency, adjust and calibrate if necessary.

- Check engine RPM; correct if necessary

- Transfer power back to utility and check

- Review transfer switch performance

- Re-torque intake and exhaust manifolds when needed

- Check and replace air filter when necessary

- Change oil and filter

- Check and change spark plugs when necessary

- Check specific gravity of battery fluid.

- Replace battery when necessary. This has an additional cost

- Shut down generator and recheck all fluid levels.

(800)779-3848

13 KW HOME GENERATOR FOR SALE. TURNKEY INSTALLATION INCLUDED.

SPECIAL PRICING LIMITED TIME ONLY!!!

$14999.00

READ BELLOW FOR DETAILS

License Number ES12000317